- Jiangsu

- + 86 13605261217

- saleslucy001@gmail.com

Energy

Production Capacity

Defect rate

Artificial

Shaping | Drying | Heat Setting | Coating

A stenter machine, also known as a stenter frame. It is a very important equipment in the textile finishing industry, which properly stretches fabric to its equally posed width, along with making it pass through a heated chamber. The fabric’s primary purpose is to impart dimensional stability, and apply treatments like heat setting, drying, and chemical finishes are applied to it in a controlled, uniform manner that enables the final product to be dimensionally stable, meeting specified quality determinants.

Fully compatible with Woven, Knitted, and Non-woven fabrics.

Reduces product changeover time from 30 minutes to just 3 minutes.

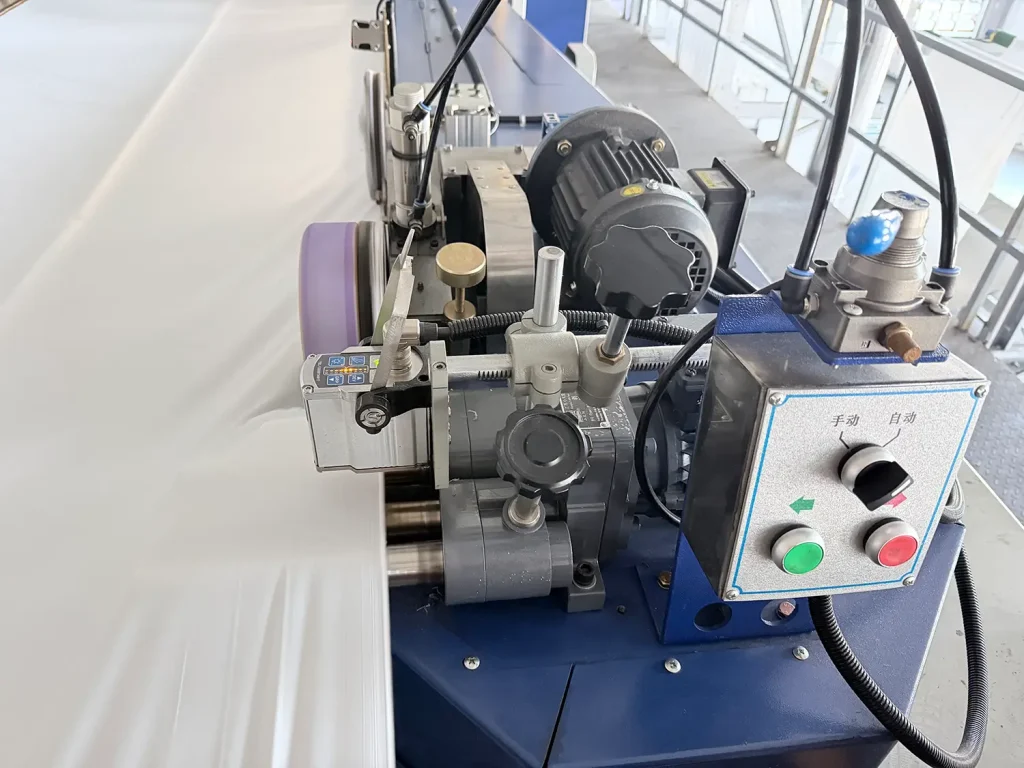

Hydraulic Anti-Deflection Roller+Variable Linear Pressure Control+Smart Protection System

Ø305mm / Ø355mm

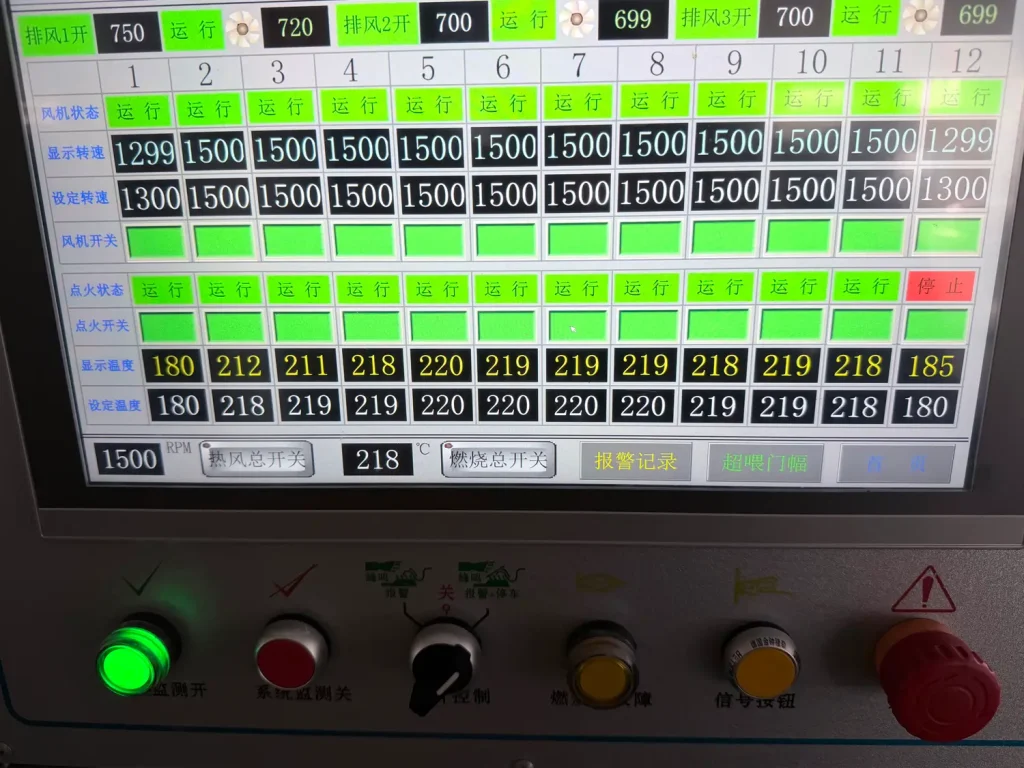

5 Heating Methods + Intelligent Switching Control + Energy-Saving Optimization

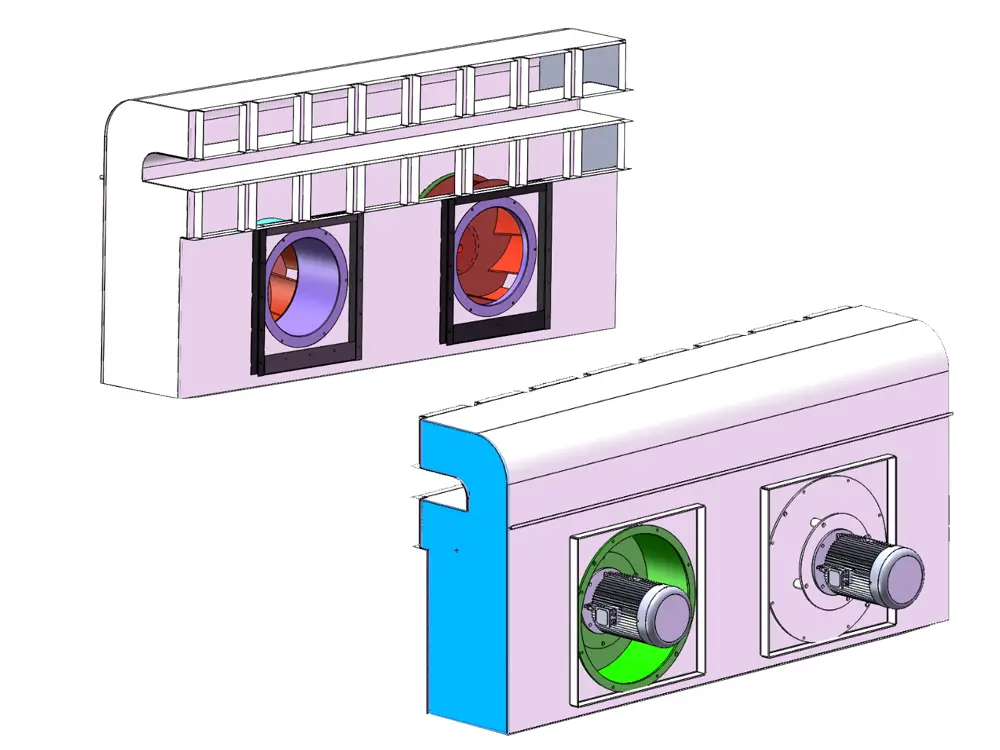

1500mm long finned

Compatible wit 100+ processes

Independent Upper/Lower Airflow + Intelligent Air Ratio Control + High-Efficiency Duct Structure.

20% increase in fan efficiency

Contact our engineers now to get a free customized solution and detailed quote.

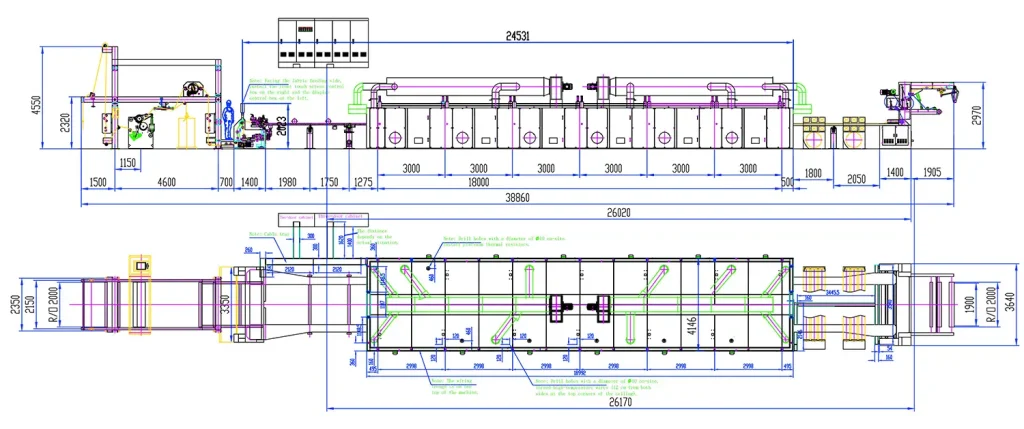

| Parameter | Technical Specification | Remarks |

|---|---|---|

| Working Width | 1200-4200 mm | Available in 50mm increments |

| Production Speed | 2-100 m/min | Inverter speed control |

| Fabric Weight | 100-500 gsm | Suitable for various fabric types |

| Max. Operating Temp. | 200 °C | Accuracy: ±1°C |

| Heating System | Various options | Natural gas burner, thermal oil, steam, or electric |

| Max. Linear Pressure | 500 N/cm | Uniform pressure distribution |

| Overfeed Adj. Range | -15% ~ +70% | Adjustable via touch screen |

| Chain System | PIN / CLIP / COMBI | Various configurations available |

Investing in our setting machine is a wise financial decision with a short payback period. For example, the approximate costs of investing are:

1. Equipment purchase cost: $350,000; 2. Transportation and insurance costs: $42,850; 3. Installation and commissioning costs: $4,000; 4. Infrastructure modification costs (preparing the site for the new equipment, which may include ground reinforcement, power capacity increase, exhaust ducting, and heat source (natural gas/thermal oil) pipeline installation): $28,571; 5. Auxiliary equipment costs (e.g., exhaust gas treatment equipment (environmental requirements), heat recovery system, etc.): $23,076

Total investment cost = $409,927

How many years will it take to recover the investment?

If the old equipment’s annual gas/electricity cost is $514,285, our machine can save $100,000 in energy costs annually.

Labor cost savings: $28,571

The equipment offers precise control. For example, the annual value of processed fabric is $7,000,000. The old equipment had a defect rate of 3%, while the new equipment reduces it to 0.5%. Annual quality control cost savings: (3% – 0.5%) × $7,000,000 = $175,000

Equipment maintenance savings: $17,000

The new equipment improves product quality and efficiency, resulting in additional profits of $72,000.

Payback Period = Total Investment Cost / Average Annual Net Income = $409,927 / $392,571 = 1.25

The investment can be recovered in just over one year.

Please enter valid positive numbers.

We will contact you within 1 working day, please pay attention to the email with the suffix “@gmail.com”.