Relax Dryer Buying Guide: Textile Industry Loose Dryer Selection Tips & HAPPY Brand Recommendation

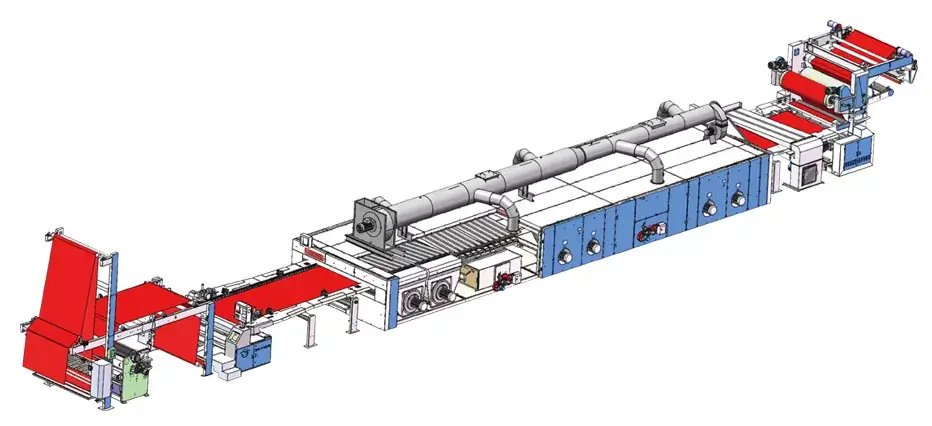

In the textile dyeing and finishing process, Relax Dryer serves as a core equipment, directly determining the hand feel, dimensional stability and final quality of fabrics. Whether it is pure cotton, chemical fiber, woolen or blended fabrics, the loose dryer maintains the fabric in a natural state both vertically and horizontally through tension-free drying technology, effectively improving fabric softness and eliminating potential shrinkage hazards. For textile enterprises, choosing the right loose dryer can not only optimize production efficiency, but also enhance the core competitiveness of products. This article will break down the core points for selecting a Relax Dryer, and combine the advantages of the HAPPY brand to provide professional selection references for industry practitioners.

I. Clarify Core Needs: Match Fabric Types and Production Scenarios

The primary prerequisite for purchasing a Relax Dryer is to align with your own production needs. Different fabric characteristics and processing scenarios have significant differences in equipment requirements. Blind selection may lead to equipment idleness or substandard product quality.

1. Precise Adaptation by Fabric Type

There is a wide variety of textile fabrics, each with distinct requirements for drying processes:

-

① Knitted Fabrics (Open Width/Circular): Knitted fabrics have high elasticity and are prone to deformation. It is crucial to focus on the equipment's overfeed adjustment capability and tension control precision to ensure the fabric's coil structure is not damaged during drying. The HAPPY Relax Dryer is equipped with an adjustable overfeed roller device, with an overfeed range of -10% to 80%, which can accurately adapt to the processing needs of circular knitted fabrics and open-width knitted fabrics, avoiding fabric stretching and deformation.

-

② Woven Fabrics/Flat Fabrics: These fabrics have a relatively stable structure but high requirements for dimensional stability. It is necessary to select equipment with good drying room temperature uniformity and sufficient fabric capacity to ensure consistent overall drying effect of the fabric.

-

③ Chemical Fiber/Blended Fabrics: Chemical fiber fabrics have large differences in heat resistance (such as polyester, nylon, spandex, etc.), requiring equipment to support multi-heat source switching and precise temperature control. HAPPY equipment is compatible with various heat sources such as steam, heat transfer oil, natural gas and electricity, with a temperature adjustment range of 100-220℃, adapting to the drying processes of different chemical fiber fabrics.

2. Align with Production Capacity and Site Planning

Production scale and workshop space directly determine equipment specifications:

-

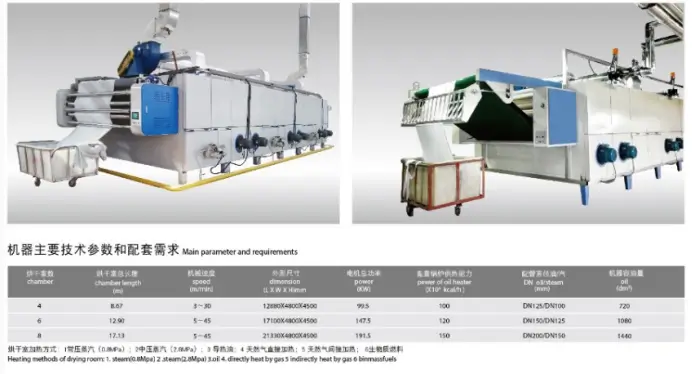

In terms of production capacity, it is necessary to select the appropriate vehicle speed and number of drying chambers according to the fabric processing volume. The speed range of conventional Relax Dryers is 5-60m/min. HAPPY can customize models according to enterprise needs, improve the unit time processing capacity by increasing the number of drying chambers (2-12 chambers optional) and optimizing the air duct design, with a maximum evaporation capacity of up to 600KgH₂O/h, meeting the needs of mass continuous production.

-

In terms of space, if the workshop space is limited, you can choose the multi-layer structure (3-layer/5-layer) HAPPY Relax Dryer, which greatly saves floor space without reducing processing efficiency; if you need to handle multiple types of fabrics, you can select a modular design model, flexibly adjust the cloth feeding device (special for open width/circular), and improve equipment versatility.

II. Focus on Core Parameters: Screen High-Quality Equipment from Three Dimensions

The performance of a Relax Dryer is determined by core parameters. When purchasing, focus on temperature control precision, air nozzle design, transmission and control systems. These indicators directly affect drying effect, energy consumption and operational convenience.

1. Temperature Control and Heat Source: Precision and Stability are Core

The stability and uniformity of the drying room temperature directly affect the color consistency and hand feel of the fabric. A high-quality Relax Dryer must meet the following requirements:

-

① Temperature Control Precision: The temperature control precision of the same section must be within ±4℃. HAPPY adopts PID adjustment and independent closed-loop control system, steam heating uses Japanese RKC temperature control instrument, and heat transfer oil heating is matched with Honeywell instrument, ensuring precise temperature control of each drying chamber and avoiding local overheating or insufficient drying of fabrics.

-

② Heat Source Adaptability: Select the heat source according to the enterprise's energy supply. Steam heat source is suitable for small and medium-sized enterprises, while heat transfer oil and natural gas heat sources have higher thermal efficiency, suitable for large-scale production. HAPPY equipment supports seamless switching of multiple heat sources, which can optimize energy consumption costs according to the actual working conditions of the enterprise.

2. Air Nozzle and Air Duct: Determine Drying Efficiency and Fabric Hand Feel

The drying principle of the loose dryer relies on hot air circulation. The design of the air nozzle and the structure of the air duct directly affect the hot air penetration and the stress state of the fabric:

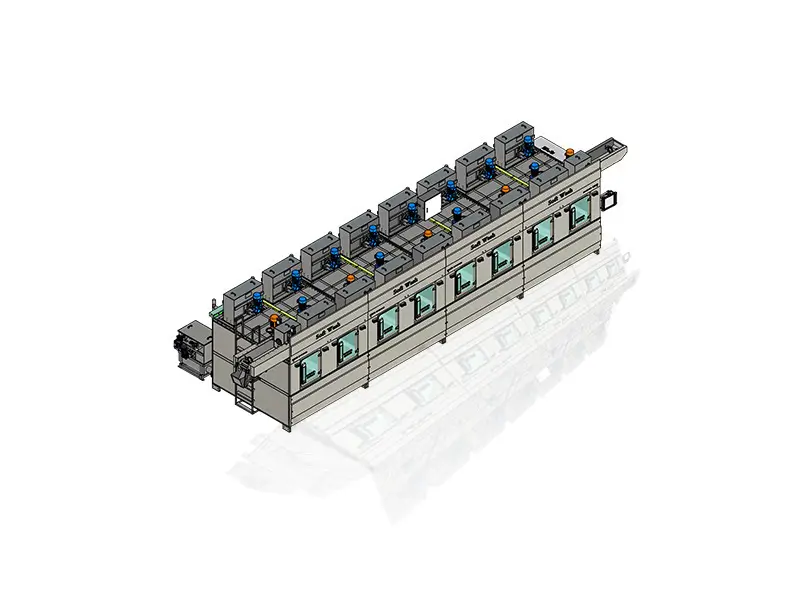

The HAPPY Relax Dryer adopts an upper and lower trapezoidal air nozzle staggered blowing design, with an air jet speed of up to 23m/sec. The hot air can evenly penetrate the fabric layer, and at the same time form a slight kneading effect, allowing the fabric to fully stretch in a tension-free state and improving the hand feel softness. The air duct is equipped with an air volume equalizer to ensure consistent air volume and speed in each area, avoiding color difference or hand feel difference caused by uneven fabric drying. In addition, the equipment is equipped with high-efficiency circulating fans (2 units of 7.5Kw fans per chamber), with an air volume of up to 24000m³/h, which greatly improves the thermal cycle efficiency and saves more than 15% energy compared with ordinary equipment.

3. Transmission and Control: Ensure Stable Operation and Easy Operation

The equipment's transmission system and control system are related to production continuity and operation difficulty, especially suitable for enterprises with multi-variety and small-batch production:

-

① Transmission System: Frequency conversion speed regulation transmission is selected to accurately adjust the mesh belt speed, overfeed amount and cloth output speed. HAPPY equipment adopts AC frequency conversion speed regulation technology, and the mesh belt, overfeed roller and cloth dropping mechanism are independently speed-regulated to ensure stable fabric operation and avoid stretching deformation. The conveyor mesh belt is made of American Chemfab glass fiber material, coated with polytetrafluoroethylene on the surface, which is high temperature resistant (up to 232℃) and tensile resistant. It is equipped with automatic tension adjustment and deviation correction device, reducing mesh belt wear and extending service life.

-

② Control System: Prioritize equipment with PLC intelligent control and touch screen operation. HAPPY is equipped with a fully automatic control system, supporting preset temperature and mesh belt speed combination parameters according to fabric type and moisture content, one-key process switching, and reducing product changeover time to less than 10 minutes. At the same time, it has multiple safety functions such as mesh belt deviation protection and over-temperature alarm to ensure production safety.

III. Pay Attention to Additional Advantages: Energy Consumption, Maintenance and Customization Capability

In addition to core performance, the equipment's energy consumption level, maintenance convenience and customization capability directly affect long-term operation costs and production flexibility, which are important plus points when purchasing.

1. Energy Consumption Optimization: Reduce Long-Term Operation Costs

Energy consumption accounts for a high proportion in textile enterprises. As a high-energy-consuming equipment, the loose dryer's energy-saving design is particularly important. The HAPPY Relax Dryer reduces energy consumption through three designs: first, it adopts a 100mm thick rock wool insulation drying room with low heat loss; second, it is equipped with an exhaust fan frequency conversion adjustment system to dynamically adjust air volume according to drying needs and avoid energy waste; third, it optimizes the heat exchanger structure, adopting a bimetallic finned heat exchanger, which improves the heat exchange efficiency by 20% and further reduces energy consumption.

2. Easy Maintenance: Reduce Downtime

Equipment maintenance costs and downtime directly affect production efficiency. HAPPY fully considers maintenance needs in design: a fan maintenance channel is reserved in the drying room to facilitate equipment cleaning and component maintenance; rotating parts adopt a sealed design, which can maintain flexible operation by regularly adding lubricating grease; the heat exchanger and filter screen support quick disassembly and cleaning, avoiding the accumulation of lint and dust affecting drying efficiency, and only simple cleaning per shift is required to maintain stable equipment operation.

3. Customization Capability: Adapt to Special Process Needs

Different textile enterprises have different process needs, and standardized equipment may not be fully adapted. HAPPY can provide full-process customization services, adjusting the machine's nominal width (1400-3600mm optional), number of drying chambers, cloth feeding/cloth output devices according to enterprise needs, and can also add automatic ash cleaning devices, residual moisture controllers, anti-static protection systems, etc., to meet special process needs such as resin treatment, loose drying and shrinkage drying.

IV. HAPPY Relax Dryer: The Preferred Partner for Textile Enterprises

As a brand focusing on textile dyeing and finishing equipment, HAPPY always takes "precision, efficiency and energy saving" as the core, creating Relax Dryers suitable for various textile scenarios. With excellent product quality and a complete service system, it has become a trusted choice for many textile enterprises around the world.

The HAPPY Relax Dryer not only has the above core advantages, but also has passed the ISO9001 quality system certification. The core components of the equipment are all selected from international well-known brands to ensure operation stability and service life. At the same time, HAPPY provides a full-cycle service from equipment selection, installation and commissioning, operation training to after-sales maintenance. The professional technical team responds to fault needs within 72 hours, minimizing production losses for enterprises.

V. Purchase Summary: Avoid Misunderstandings and Make Precise Selections

When purchasing a Relax Dryer, it is necessary to avoid two major misunderstandings: "only focusing on price rather than performance" and "blindly pursuing high configuration". Prioritize aligning with your own fabric type, production capacity and process needs, focus on core parameters such as temperature control precision, air nozzle design and transmission control, and then consider energy consumption, maintenance and customization capabilities. HAPPY recommends that enterprises conduct on-site inspections and sample tests before selection to ensure the equipment is highly matched with production needs.

A high-quality Relax Dryer is the key for textile enterprises to improve product quality and reduce operation costs. With customized solutions, stable performance and thoughtful services, the HAPPY Relax Dryer helps textile enterprises stand out in the fierce market competition. To obtain an exclusive selection plan, you can contact the official HAPPY team for one-on-one professional consulting services.