- Jiangsu

- + 86 13605261217

- saleslucy001@gmail.com

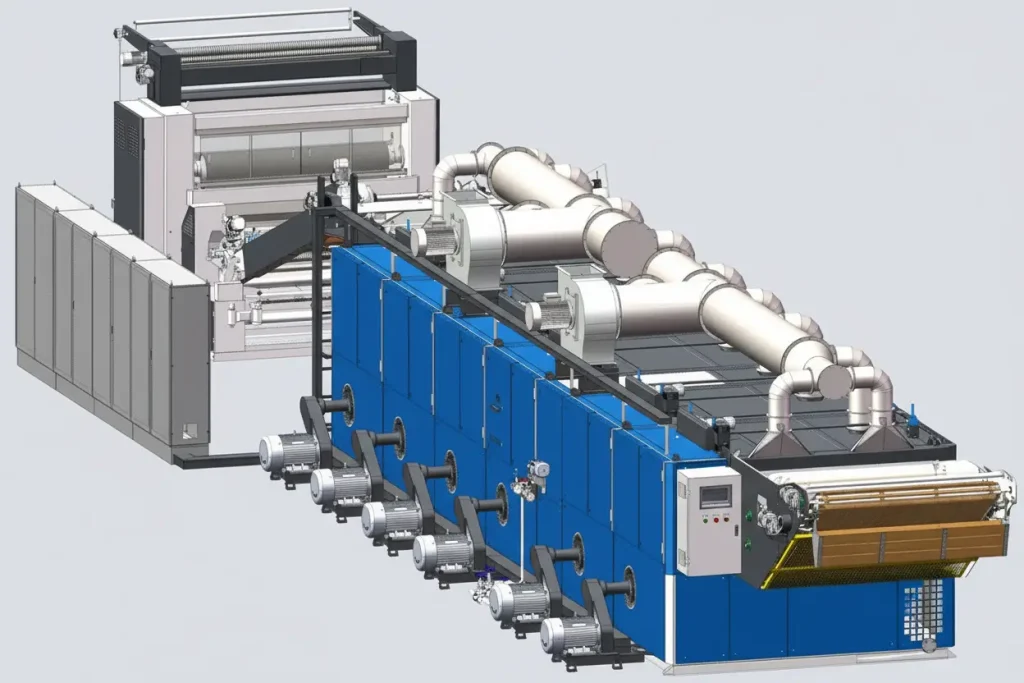

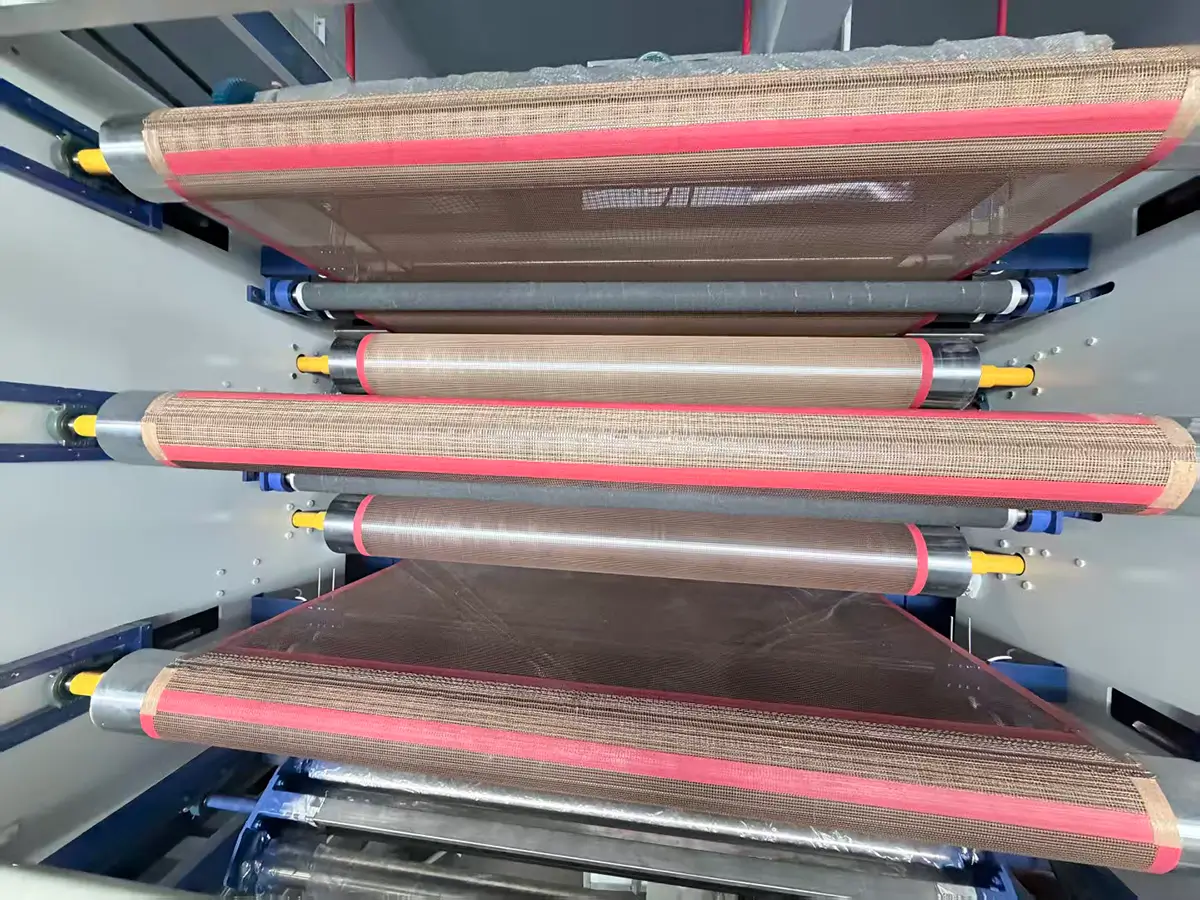

The relaxed-drying machine utilizes an innovative three-channel mesh belt conveying system, allowing fabrics to be fully relaxed, dried, and pre-shrunk in a completely tension-free, “wavy” state.

Whether it’s delicate knit fabrics, high-stretch fabrics, or special fabrics such as towels, velvet, and coral fleece, it delivers unparalleled fluffy texture, stable weight, and extremely low residual shrinkage, making it the ideal choice for improving fabric quality and winning over high-end markets.

Energy efficiency

Fabric residual shrinkage rate

Working width

Suitable for the fabric

The relax dryer carries the fabric on a conveyor belt, allowing it to pass through the drying chamber in a completely relaxed state, utilizing a hot air circulation system for even drying.

1. Feeding and Spreading: The fabric is fed through a fabric feeding device and relaxed guide rollers, and then smoothly spread onto a continuously moving conveyor belt (usually made of polyester or metal mesh).

2. Relaxed Transport: The conveyor belt carries the fabric steadily through the high-temperature drying chamber. Because the fabric “rests” on the conveyor belt, it is not subjected to any longitudinal tension and remains in a relaxed state.

3. Hot Air Drying: Heaters (electric, steam, gas, or thermal oil) in the drying chamber heat the air, and powerful circulating fans force the hot air vertically through the fabric and conveyor belt from top to bottom or bottom to top. This through-flow heating is highly efficient and ensures even heating.

4. Cooling and Output: After drying, the fabric is cooled in a cooling zone and then neatly folded or wound up by a fabric output device.

Revolutionary technology integration for optimal performance

Dual feed structure + pneumatic tension control + infrared automatic alignment

The fabric shrinkage rate is precisely controlled at 8-10%.

Fabric quality has improved by 40%.

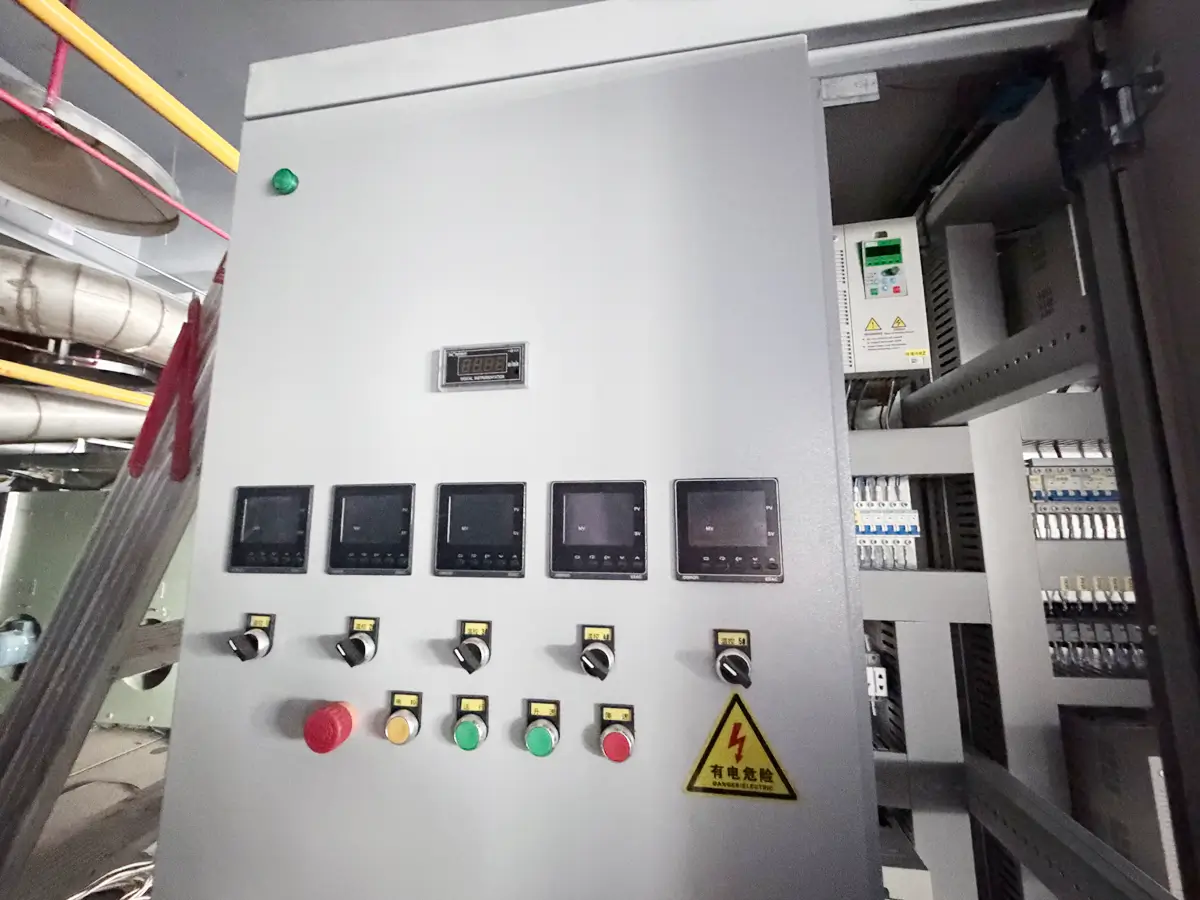

Siemens PLC + touchscreen + humidity sensor

40% better than competitors.

Less investment, higher returns.

Independent variable-frequency motor direct drive + pneumatic edge guiding + belt anti-deviation protection

99.9% fault-free operation

Detachable drying chamber + double-layer stainless steel filter screen + external motor design

Reduce 50%

Long-term stability, preservation of asset value.

Contact our engineers now to get a free customized solution and detailed quote.

Comprehensive technical parameters and optional configurations

Core Drive & Control:

Tension & Alignment System:

Hot Air Circulation System:

Insulation & Energy-Saving System:

World-Class Brand Components:

Real-time moisture monitoring and automatic adjustment

Energy-efficient heat recovery technology

Enhanced fabric preparation and alignment

We will contact you within 1 working day, please pay attention to the email with the suffix “@gmail.com”.