Minimum moisture content, significantly reduced drying energy consumption

Compared to traditional equipment, saving hundreds of thousands annually

24/7 online pressure adjustment to eliminate substandard products

It Saves on expensive dyes and auxiliary chemicals.

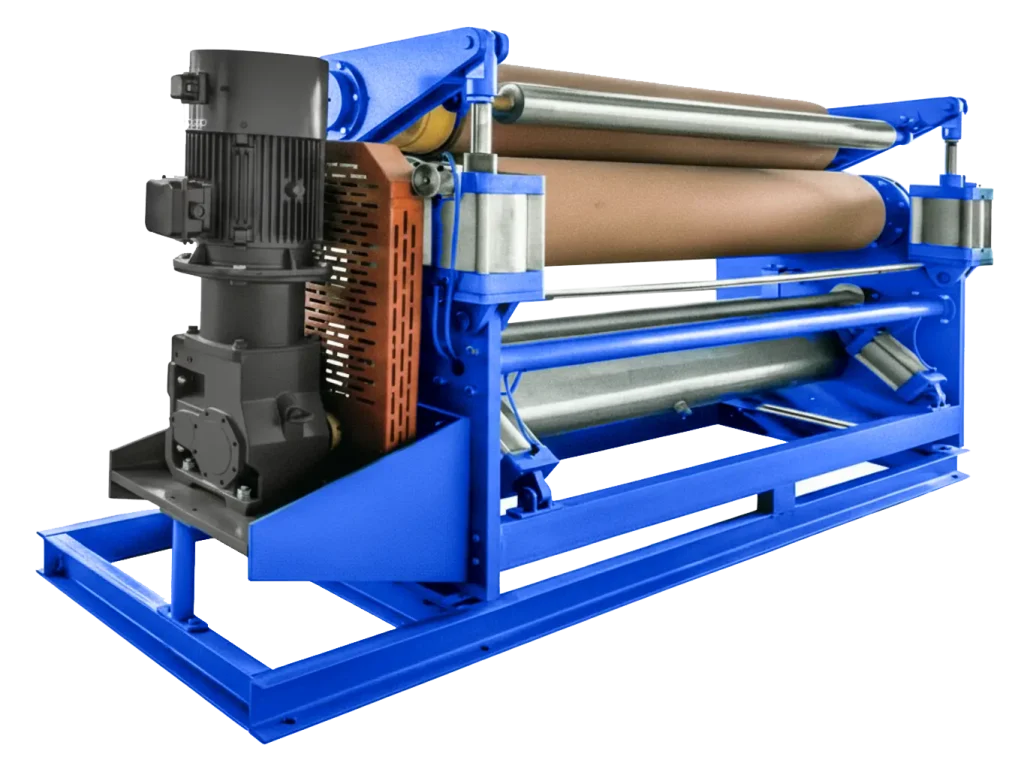

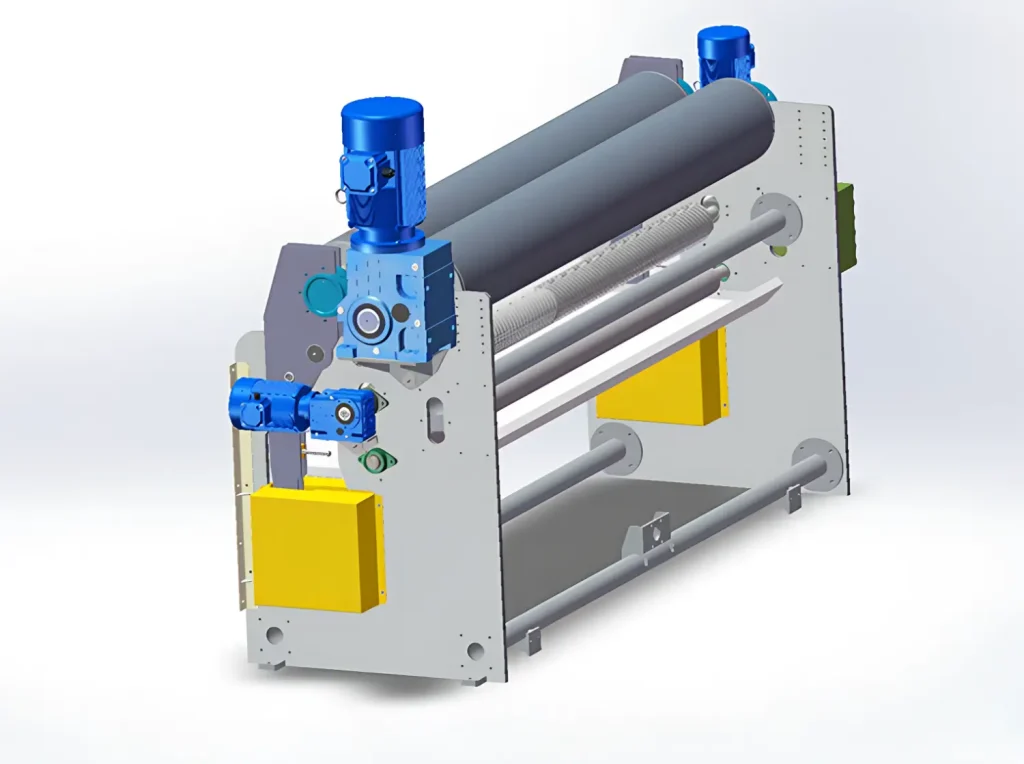

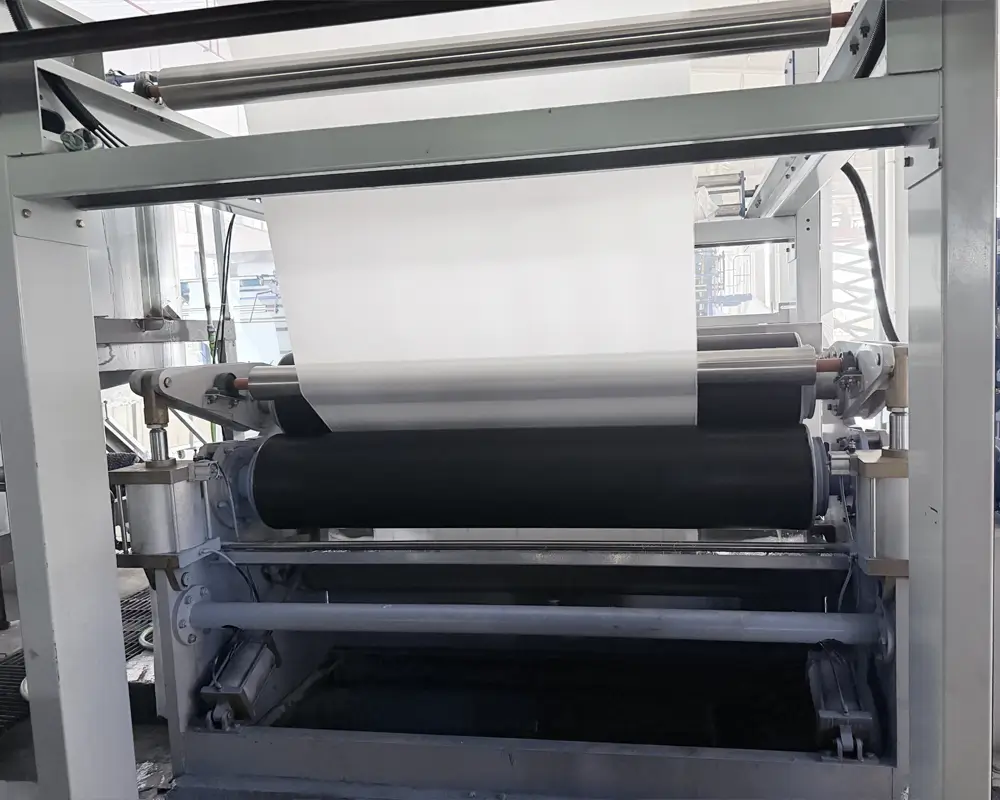

Padding mangle machine is a general term for equipment that processes fabrics through immersion and pressure treatment using rollers. Its core function is to immerse the fabric in a liquid bath and then evenly squeeze out the excess liquid using two (or more) high-pressure rollers.

Happy Padding Machines optimize existing production lines, such as mercerizing machines, scouring and bleaching combined machines, and setting machines, to efficiently complete immersion padding or coating finishing. This ensures consistent fabric color, eliminates color differences, and provides uniform functional finishing effects.

It features multiple sets of evenly distributed pressure rollers with adjustable pressure on the left, center, and right sides to control edge-to-center variations.

Reactive dyes and alkalis can be applied separately and continuously in the same machine. The first padding has a liquid pick-up rate of 40-60%, and the second padding has a rate of 70-120%.

The dyes and alkalis do not come into contact during application, reducing hydrolysis and eliminating head-to-tail color differences. Other dyes or finishing agents can be applied continuously through multiple padding passes, ensuring excellent uniformity.

The padding machine rollers use Spanish-imported rubber, which is resistant to aging, oil, corrosion, and bending.

PLC-controlled Padder + online wet pick-up sensor + independent L-C-R pressure control.

cover all fabrics type, including woven , knitted , and industrial textiles.

The defect ratereduce 90%, and quality stability has improved.

Spanish-made high-performance rubber roller+Stainless steel-clad roller+Bottom-up hydraulic pressure system

Ø350mm / Ø380mm

60% better application evenness, with zero side-to-center difference.

Separate application of dye and alkali+ Multi-stage successive padding +Controlled uniform distribution

Minimizes dye hydrolysis, eliminating start-to-end color variation;Ensures minimal fabric distortion and tension.

Automatic Trough Cleaning+Online Oil Temperature Monitoring

Annual maintenance cost savings of 200,000-300,000.

Contact our engineers now to get a free customized solution and detailed quote.

| Parameter | Specification |

|---|---|

| Nominal Width | W(1800-3600)mm |

| Roller Diameter | Center 380mm |

| Pressure Method | Bottom-up Hydraulic |

| Design Maximum Speed | 35-150 m/min |

| Total Pressure | 5T |

| Roller Configuration | Active Roller (Center): Stainless steel coated roller, Ø350mm |

| Passive Rollers (Top & Bottom):2 rubber rollers, Ø350mm each |

The cost of a padding machine varies, starting from approximately $10,000 for laboratory-scale models and exceeding $200,000 for full-scale industrial systems. The final price is contingent upon specifications such as roller composition, degree of automation, operational width, and the scope of after-sales service provided by the vendor.

An investment in our intelligent padding machine yields a swift return, with a projected payback period of 12 to 18 months. Profitability is achieved through significant and quantifiable cost savings:

Energy Consumption Reduction (20-30%): Enhanced de-watering efficiency directly reduces the energy load on subsequent drying stages, a major component of operational expenditure.

Chemical & Dyestuff Cost Reduction (10-15%): AI-powered process control ensures uniform application, thereby eliminating material waste and over-application.

Labor and Sampling Cost Reduction (>50%): Full automation, including recipe management, obviates the need for extensive manual oversight and laboratory sampling.

Quality & Yield Improvement: The system effectively eliminates color deviation, leading to a 3-5% increase in first-pass yield and a corresponding reduction in defective products.

We will contact you within 1 working day, please pay attention to the email with the suffix “@gmail.com”.